Understanding the Importance of Pharmaceutical Packaging

Pharmaceutical packaging plays a crucial role in ensuring the safety, stability, and effectiveness of medications.

The Role of Packaging in Pharmaceutical Safety

Pharmaceutical packaging serves as the first line of defense in protecting medications from contamination, damage, and tampering. It is designed not only to preserve the integrity of the product but also to ensure that the drug remains effective throughout its shelf life. A well-designed package prevents exposure to moisture, light, oxygen, and other environmental factors that can degrade the medication. Moreover, tamper-evident features and child-resistant closures add another layer of safety for both healthcare providers and consumers.

Key safety functions of pharmaceutical packaging include:

- Preventing contamination through sterile sealing and barrier materials

- Maintaining chemical stability by shielding from light and moisture

- Providing tamper evidence to assure consumers of product integrity

- Offering child-resistant features to prevent accidental ingestion

These measures are essential for patient safety and regulatory compliance, making packaging a critical part of the pharmaceutical supply chain.

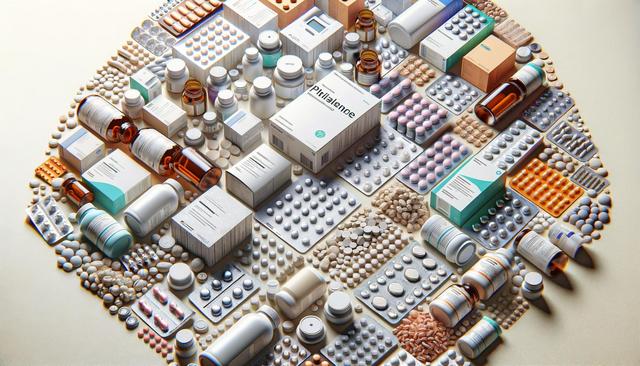

Types of Pharmaceutical Packaging

There are various types of pharmaceutical packaging tailored to different drug forms, such as tablets, capsules, liquids, and injectables. Each type is chosen based on the specific requirements of the medication and how it will be used by the patient. The most common packaging formats include:

- Blister packs – ideal for individual dosing and patient compliance

- Bottles – commonly used for liquids and bulk tablets

- Ampoules and vials – used for injectables and sterile solutions

- Sachets and pouches – for powders and small doses

Blister packaging is particularly beneficial for solid oral dosage forms, offering protection and ease of use. Meanwhile, bottles are often used for over-the-counter medications due to their cost-efficiency and simplicity. Injectable drugs, which require sterility, are stored in glass ampoules or vials to maintain purity and facilitate administration in healthcare settings.

Regulatory and Compliance Considerations

Pharmaceutical packaging must adhere to strict regulatory guidelines to ensure quality and safety. Agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have specific requirements regarding materials, labeling, and testing. These regulations are designed to prevent counterfeiting, ensure traceability, and provide accurate information to patients and healthcare providers.

Key compliance aspects include:

- Accurate and clear labeling of dosage, warnings, and usage instructions

- Use of approved materials that do not interact with the drug

- Serialization and barcoding for traceability

- Stability testing to confirm packaging effectiveness over time

Meeting these standards is essential for pharmaceutical companies to bring their products to market and maintain consumer trust. Failure to comply can result in recalls, legal consequences, and damage to brand reputation.

Innovations in Pharmaceutical Packaging

Advances in technology have transformed pharmaceutical packaging, leading to smarter, safer, and more sustainable solutions. From smart labels that monitor temperature to eco-friendly materials, innovation is driving improvements in both functionality and environmental impact. Digital packaging, for instance, integrates QR codes and NFC chips that allow users to access detailed product information using their smartphones.

Emerging trends in pharmaceutical packaging include:

- Smart packaging with sensors for real-time monitoring

- Eco-friendly materials such as biodegradable plastics and recyclable cartons

- Personalized packaging for targeted therapies

- Anti-counterfeiting features using holograms and blockchain

These developments not only enhance user experience and compliance but also support global efforts toward sustainability in healthcare. Companies that invest in innovative packaging can differentiate their products and respond to evolving consumer expectations.

The Future of Pharmaceutical Packaging

The future of pharmaceutical packaging lies in the integration of technology, sustainability, and patient-centric design. As the pharmaceutical industry continues to grow and diversify, packaging must adapt to new drug delivery methods, stricter regulations, and greater consumer awareness. Personalized medicine and biologics, for example, require packaging that is both advanced and adaptable.

Looking ahead, we can expect to see:

- Greater use of automation and robotics in packaging lines

- Increased emphasis on user-friendly designs that support adherence

- Wider adoption of sustainable practices and materials

- Enhanced data integration for supply chain transparency

By embracing these changes, pharmaceutical companies can improve patient outcomes, reduce waste, and build stronger relationships with healthcare providers and end users. Packaging will continue to evolve from a protective shell to an active participant in the healthcare journey.

Conclusion: Aligning Packaging with Patient Needs

Pharmaceutical packaging is more than just a container—it’s a critical component in the safe and effective delivery of healthcare. With growing expectations around safety, sustainability, and patient engagement, the industry must continue to innovate and adhere to rigorous standards. Whether through advanced materials, smart features, or eco-conscious design, packaging solutions that align with patient needs will help foster trust and support better health outcomes. For manufacturers, investing in thoughtful and compliant packaging is not just a regulatory requirement—it’s a strategic advantage in a competitive and responsible marketplace.